Tech war: China’s semiconductor ambitions face reality check amid reports US is set to widen ban on exports of equipment to country

- US semiconductor equipment suppliers Lam Research and KLA Corp confirmed that the US has been pushing for stricter export regulations

- The new restrictions come at a time when Washington is pressing the Dutch to block ASML from exporting DUV machines to China

China’s semiconductor self-sufficiency drive could face another hurdle as the United States moves ahead to widen the scope of its equipment export ban to China, analysts say.

US semiconductor equipment suppliers Lam Research and KLA Corp confirmed that the US government has been pushing for stricter export regulations to China by covering equipment needed for manufacturing chips at 14-nanometre and below, according to a Bloomberg report. If that is confirmed officially, it would mark an escalation from the previous ban covering 10-nm and below – the most advanced end of chip-making technology.

The new restrictions come at a time when Washington is pressing the Dutch government to block ASML from exporting less advanced deep ultraviolet (DUV) lithography systems to China, which ASML CEO Peter Wennink described on a recent earnings call as a “a political position which we have to wait for politicians to come up with”.

Analysts said reports of a wider equipment ban could make it harder for China to reduce its reliance on imported chips as such equipment, which the country is unlikely to be able to make in the near term, is essential for producing chips.

“It could be a big problem for China-based foundries but it remains to be seen how broadly these restrictions are applied,” said Sravan Kundojjala, a senior analyst at Strategy Analytics. “Foundries need equipment from multiple vendors, and even without the support of one vendor, things can fall apart.”

Wang Xiaolong, research head at Shanghai-based semiconductor consultancy ICWise, said the US move heralds more difficulties ahead for local foundries as they seek to import key equipment.

Meanwhile, both Lam Research and KLA value the Chinese market as an important driver of growth after the country became the world’s largest integrated circuit (IC) consumer market.

Revenue from mainland China accounted for 35 per cent of Lam Research’s total revenue of US$14.6 billion in financial year 2021, up from 31 per cent in 2020 and 22 per cent in 2019 respectively. Lam Research is one of the top three US semiconductor manufacturing equipment suppliers and leads the field in deposition and etch products.

US chips act casts shadow over Beijing’s semiconductor self-sufficiency drive

KLA made 26 per cent of its financial year 2021 total revenue of US$6.92 billion from customers based in mainland China, the highest share across its geographic segments and ahead of the shares of Taiwan, South Korea and Japan with 25 per cent, 19 per cent, and 9 per cent respectively. KLA is a global supplier of process control tools.

Both companies cautioned on risks ahead for China-related business in their 2021 financial reports in light of the US Entity List, which has restricted their ability to provide products and services to entities such as Semiconductor Manufacturing International Corp (SMIC) without an export licence.

Sanctions-hit SMIC, China’s largest foundry, has already shifted its focus away from developing advanced technology at 10-nm and below to mature technology of 28-nm and above, after its inclusion in the US trade blacklist in December 2020.

However, Canada-based semiconductor research company TechInsights recently said SMIC had made a breakthrough in producing 7-nm chips without using cutting-edge extreme ultraviolet lithography (EUV) systems, although no details were given regarding SMIC’s manufacturing yields at this more difficult technology node.

SMIC’s most advanced technology, officially, is 14-nm FinFet, which entered mass production in the second half of 2019. SMIC is also working on 12-nm, dubbed FinFet N+1, but details on progress remain unclear.

TikTok owner ByteDance looks to design in-house chips, joining rivals

SMIC’s Chinese rival, Hua Hong Semiconductor, is also developing 14-nm tech for logic chips, but the company’s top revenue-generating processes are 350-nm and 90-nm, which combined, accounted for 60 per cent of its first-quarter revenue.

Taiwan Semiconductor Manufacturing Corp (TSMC), the world’s largest contract chip maker, has a fab producing chips at 16-nm in eastern Nanjing, capital of Jiangsu province.

The technology is three generations shy of its most advanced node in mass production of 5nm, operated by its Taiwan-based foundry.

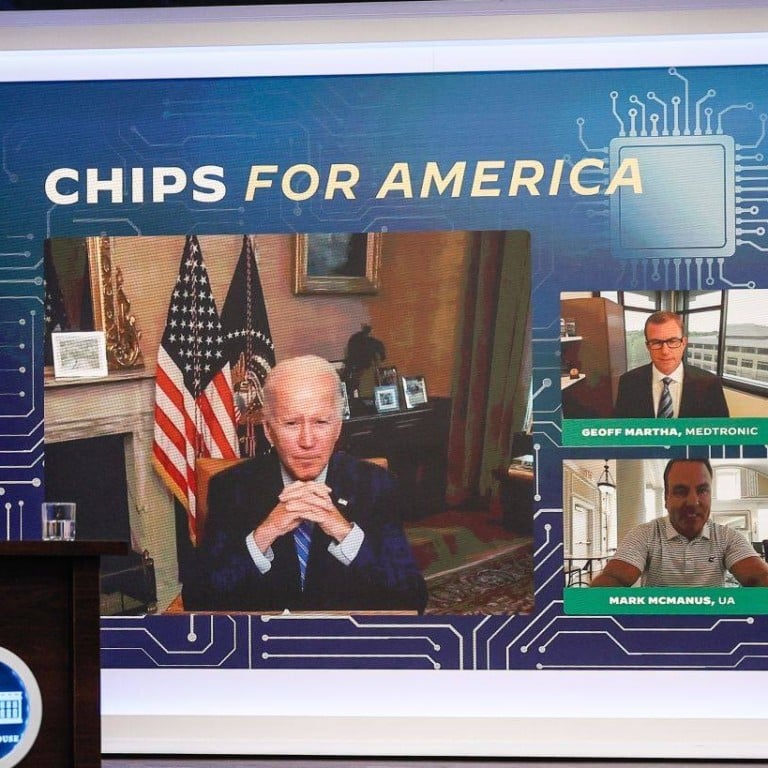

Meanwhile, the Chips and Science Bill, which was passed by the US Congress and which is expected to become law soon, is expected to revive US domestic semiconductor manufacturing with US$52.7 billion in subsidies.