Advertisement

Chinese scientists develop cutting-edge tech for 3D ceramic printing in the air to create complex engineering parts

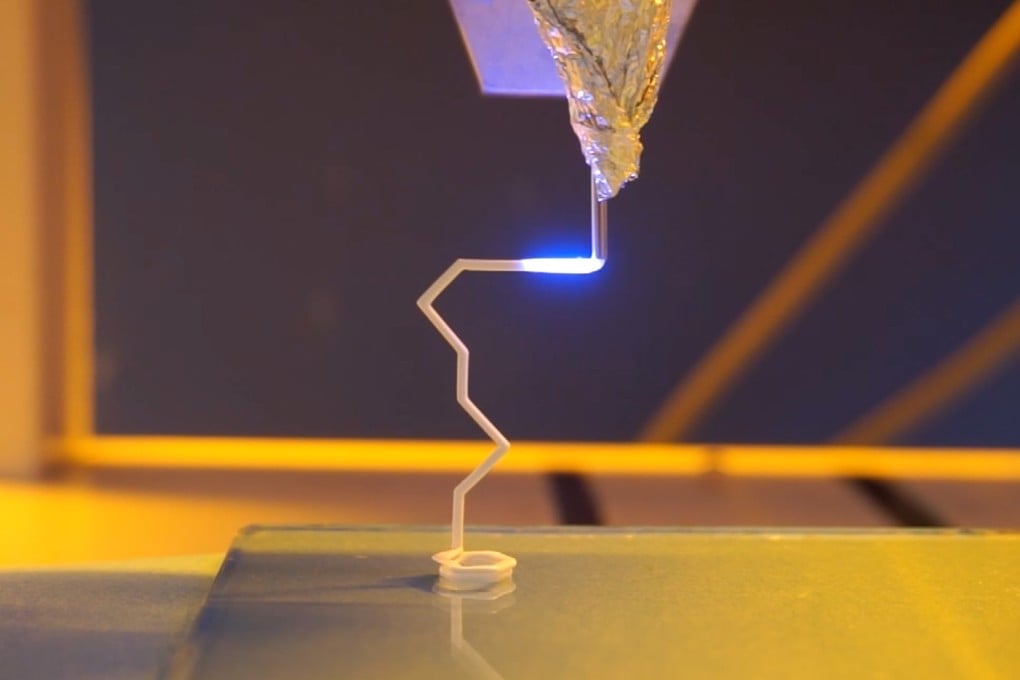

- Jiangnan University team creates new printing paste and improved curing technique to boost printing efficiency and remove need for support structures

- Ceramics are widely used in mechanical engineering, electronics and aerospace fields but their brittleness and hardness make manufacturing a challenge

Reading Time:3 minutes

Why you can trust SCMP

14

Zhang Tongin Beijing

Scientists in China have developed a new technique for 3D printing of ceramics in the air without the need for supportive structures.

This cutting-edge method can construct ceramic parts at almost any angle, enabling the creation of shapes that were previously impossible for typical 3D printing techniques.

Ceramics are widely used in mechanical engineering, electronics and aerospace fields because of their structural stability, wear-resistance and high-temperature endurance. But the inherent brittleness and hardness of ceramics have made manufacturing intricate parts a challenge.

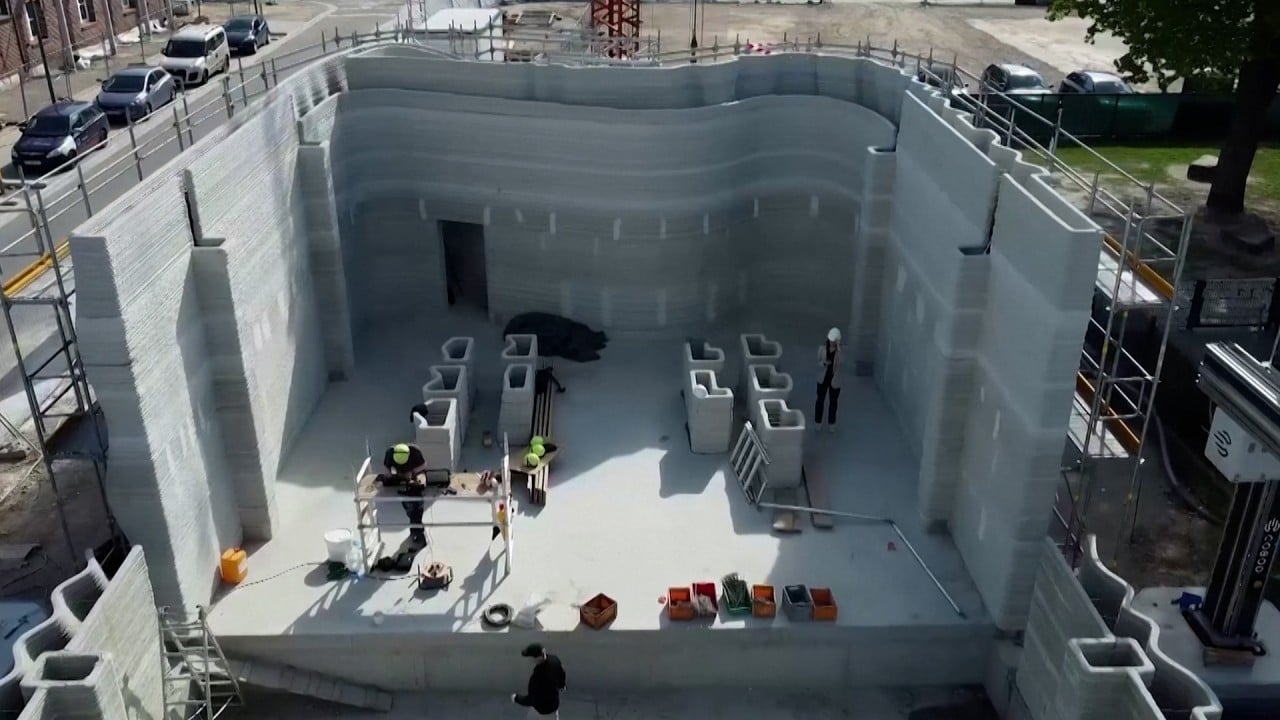

3D printing, also called additive manufacturing (AM), has offered an efficient and convenient way to produce complex ceramics with integrated structures and functions.

In traditional 3D printing of ceramics, additional supporting structures are often needed to prevent the collapse of unsupported parts. This extra skeleton not only affects printing efficiency but also raises issues related to the removal of these supports.

Advertisement