Chinese rare earth tech innovation aims for faster, cleaner extraction: paper

- Guangzhou team says their electric power method could make China even more competitive in global supply chain

- ‘Technique is viable, both environmentally and economically, revealing new paths for the sustainable harvesting of natural resources’: Professor He Hongping

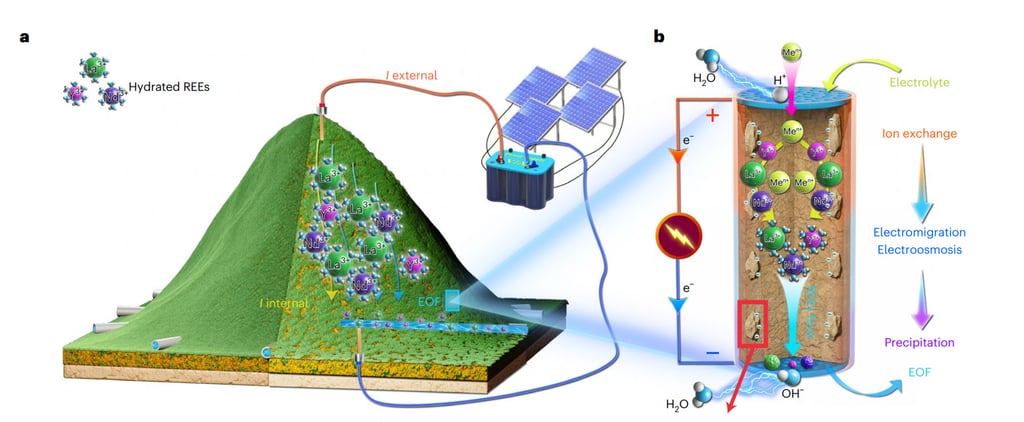

Rare earth elements are essential in various industrial and military applications but mining them is extremely time consuming and the large amount of chemicals required to separate these elements from other materials usually comes at a high environmental cost.

China plays an important role in global rare earth production, especially for elements with higher molecular weight.

“The ion-adsorption deposits in southern China supply more than 95 per cent of the global heavy rare earth elements demand,” said Professor He Hongping, head of the Guangzhou Institute of Geochemistry, Chinese Academy of Sciences, in a paper published in the peer-reviewed journal Nature Sustainability on October 31.

Traditionally, workers use ammonium sulphate as a leaching agent to extract rare earths from natural deposits, then use ammonium bicarbonate to remove impurities. Finally, they obtain ionic rare earth concentrates by roasting.

Both chemicals are harmful to the environment. Ammonium salts may penetrate into the soil and remove minerals such as calcium and magnesium that are important for plants and the ecosystem. For example, many microorganisms stop being active after chemical immersion. Restoring these minerals can be a difficult and costly process.