Hong Kong builders respond to demand for sustainable construction methods as city pursues carbon neutrality

- By reducing costs, waste and construction time, sustainable techniques present a compelling business case, says Yau Lee Holdings vice-chairman

- Government has pledged carbon neutrality by 2050, and decarbonising the city’s buildings will be crucial to meeting this goal

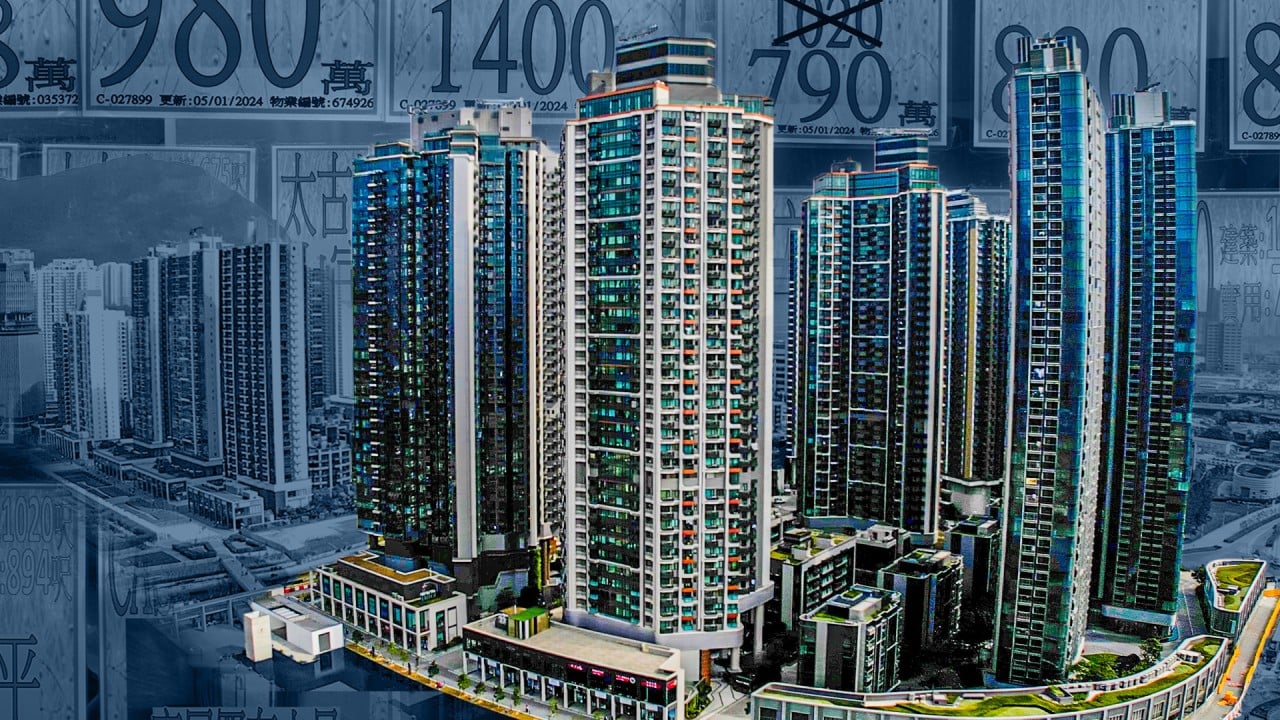

Hong Kong building contractor Yau Lee Holdings is seeing greater demand for environmentally friendly construction techniques that improve the sustainability of the built environment to help the city reach its carbon neutrality goal.

One such technique is modular integrated construction (MIC), which is becoming a mainstream construction method in the city as it not only requires less electricity and labour, but also reduces materials waste and the time it takes to complete projects, according to Conrad Wong Tin-cheung, vice-chairman of Yau Lee.

“Modular integrated construction is a trend that is becoming our company’s core competency,” said Wong, who will take part in a panel discussion on building and construction at the GreenTech Summit 2024, taking place on February 26 as part of the Hong Kong Green Week event organised by the government.

“We are trying to build a business case and demonstrate that you have to be green … and that doing good means doing well,” said Wong.

MIC involves factory assembly of free-standing modules, complete with finishes, fixtures and fittings, which are then transported to the building site for installation. Adopting MIC shortens the total construction time by about 30 per cent on average while also minimising waste, according to the Construction Industry Council.

The government first promoted MIC in 2017 as part of a push to increase housing supply.

In the five-year period starting in 2028, Lee said that at least 50 per cent of the city’s public housing projects should adopt the MIC approach, adding that the non-governmental Hong Kong Housing Society, the city’s second-largest provider of public housing behind the Housing Authority, will also adopt MIC in more projects.

The use of MIC reduced construction waste by 53 per cent, on-site air pollution by 25 per cent and on-site water and electricity consumption by 70 per cent, compared with traditional building methods, according to Yau Lee.

It also led to a 50 per cent reduction in skilled labour and accelerated the construction schedule by around four months, according to the contractor.

Yau Lee is working on seven MIC projects worth HK$20 billion, including about 20,690 units. This includes a public housing development at Tung Chung Area 99.

“As a practitioner, we really need to focus on how we can be more efficient in designing, constructing, maintaining and operating our buildings,” Wong said. “This is something that we as engineers, architects and building professionals must do.”

Builders also have to tackle buildings’ energy consumption, he said.

South Korea scientists open up ‘world of possibilities’ by growing ‘meaty rice’

Yau Lee has built other environmentally friendly projects through subsidiaries such as REC Engineering Company. This includes Hong Kong’s first floating photovoltaic system, a 100-kilowatt facility at Shek Pik Reservoir in Lantau built for the Water Supplies Department (WSD) in 2017.

A set of 352 solar photovoltaic panels was installed over the reservoir surface, which not only produces renewable energy but saves water resources by reducing evaporation, according to the WSD. The system powers pumps at the nearby Shek Pik valve tower, helping to cut electricity expenses by 25 per cent, the WSD said.

Environmentally friendly construction methods are enjoying greater demand from clients across the industry, said Wong.

“The industry is becoming more environmentally conscious,” he said. “The government already has a carbon-neutral road map for the whole of Hong Kong, and the construction sector [has] to do our own duty. Green is gold, carbon is diamond. So whenever you can actually reduce carbon emissions, that is a business case.”