3D-printed concrete buildings? Hong Kong research team hits brick wall in bid to take cutting-edge tech mainstream

- Christian Lange of the University of Hong Kong says his team can produce 3D-printed concrete objects in just minutes, potentially revolutionising building practices

- But pitch has failed to attract interest among property developers and bid for government funding still pending more than a year after application

Architect Christian Lange of the University of Hong Kong has hit a brick wall with his cutting-edge development of 3D-printed concrete, potentially hindering the chance to revolutionise building practices.

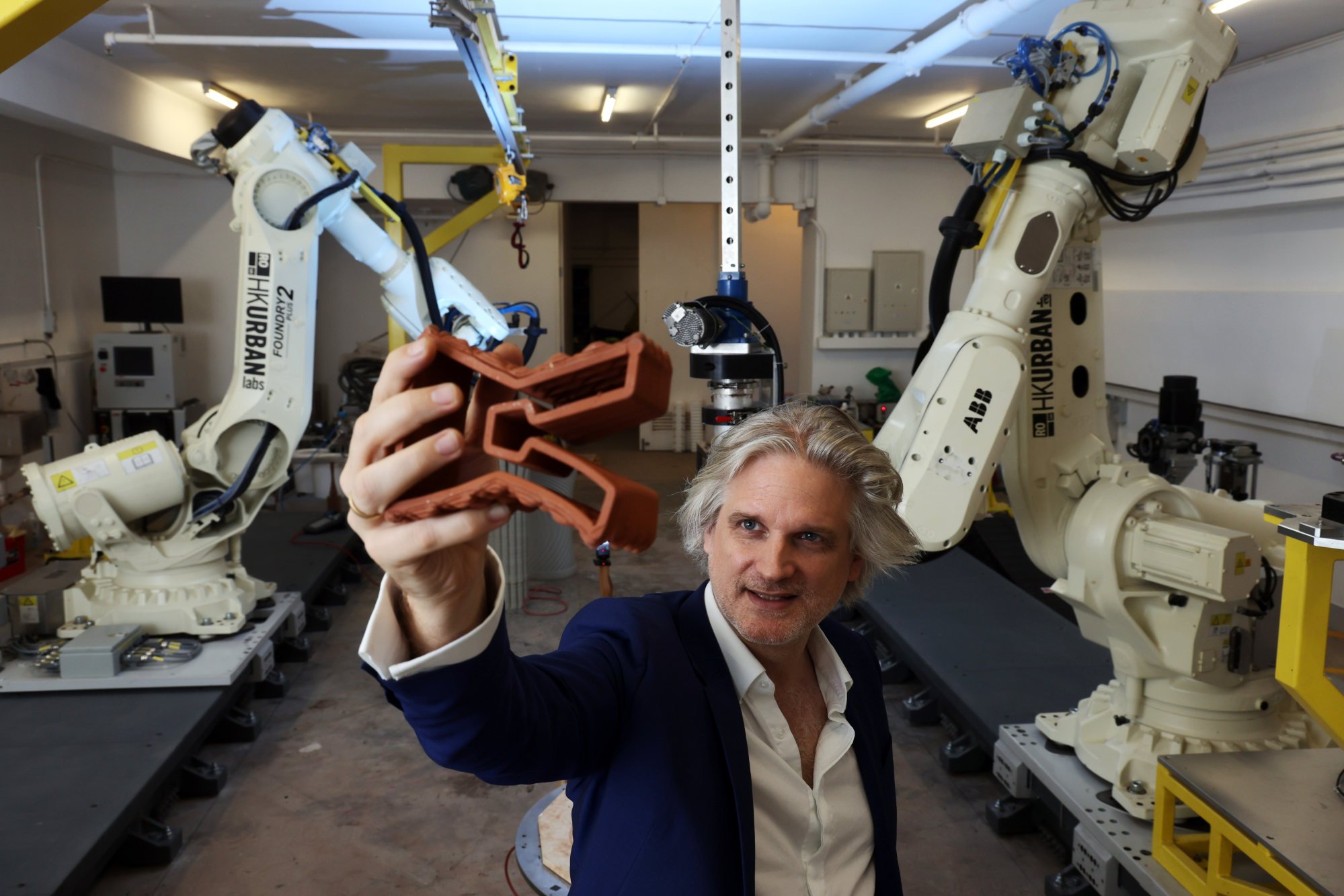

The department of architecture associate professor is excited about his newly revamped fabrication lab in a low-ceilinged car park storeroom on campus, featuring two large robots on tracks which swiftly alternate between concrete printing, picking and placing, as well as welding.

After developing a series of 3D-printed terracotta reef structures in clay, a collaborative research mission with marine scientists aimed at restoring coral in Hoi Ha Wan Marine Park in 2020, the lab is now capable of producing concrete objects in a matter of minutes.

But efforts to commercialise the research have stumbled, with Lange and his team failing to attract interest in their pitch among property developers and encountering funding hurdles.

The researchers are still waiting to hear back on their application, submitted in mid-2022, to the government’s Construction Innovation and Technology Fund.

As part of last year’s policy address in October, the chief executive announced money would be allocated in 2024 to more than 400 companies under the fund, which aims to advance the adoption of innovative technology in construction projects.

“I think our pitch was actually good but there was no real outcome, making me wonder if we should have applied for a different grant,” Lange said.

Abby Choi’s face ‘to be recreated with 3D printing’ for funeral in Hong Kong

Discussions with a private developer also fell flat.

“The developer we have been talking to … did not see the full picture,” he said. “The discussion was on hold for more than a year.

“If you get some government funding, then you seem to have more credibility. If you want to commercialise a technology, you obviously need to have a facility, which is also money-related. That would possibly be an obstacle for us.”

The Development Bureau said the government fund mostly offered subsidies for readily available technology, while 3D printing of concrete was considered an emerging area covered by the Pioneering Application, a separate initiative under the fund.

Hong Kong researchers develop 3D-printed material that kills coronavirus

A spokesman said the initiative, launched in 2022, aimed to support industry stakeholders to attract emerging but proven technologies from abroad that required adaptation and modification to be used in the local construction industry.

Lange said the technology being used by his team came from the Netherlands.

“[It uses] a so-called 2K system, which is basically concrete and an accelerator,” he said. “An accelerator is a chemical that is pumped into the concrete to make it set instantaneously.”

The bureau spokesman said applications were still being reviewed.

“The [fund’s] secretariat has received a few applications and proposals about the introduction of the 3D concrete printing technology into Hong Kong, which are now under processing pending applicants’ submission of the required justifications and information,” the spokesman said.

Lange described the 3D printing of concrete in Hong Kong as being in its “infancy”. The technology is making advances in some other parts of the world, such as in Denmark’s capital, Copenhagen, where it was used to construct a 72 square metre (775 sq ft) community building featuring a gym and laundry.

“People working with it are mostly still within the academic realm and linked to university environments, doing large test prints or prototypes and [figuring out] how to utilise this technology for architecture.”

Acknowledging that 3D-printed concrete is a new material that must comply with building regulations, the team is focusing on landscape architecture, working on non-structural elements such as flower pots, large vases and benches that could enhance the urban environment.

A one-metre (3-foot) tall vase could be printed in 20 minutes without needing to wait for it to dry, while a 3D-printed terracotta reef structure could take up to four hours, Lange said.

Legislator Tony Tse Wai-chuen, of the architectural, surveying, planning and landscape functional constituency, said authorities were very cautious about funding innovative technology projects.

“The projects must provide reports on the outcomes and effectiveness, which can lead to longer waiting times for approval,” Tse said.

“Even after a project has already incurred expenses, they may not be acknowledged during the funding approval process. But if the project’s progress is dependent on financial help, it will only stagnate.”

‘Extra pair of eyes’: Hong Kong researchers find AI helps doctors spot tumours

He added that price and production capacity were also factors to consider, as innovators using 3D-printing technology might find it difficult to compete with a factory which could produce at a larger scale.

Lange said he was willing to put his products through all kinds of tests if the technology could eventually be opened up to be used for buildings, but he would continue with smaller developments, such as creating decorative landscaping pieces.

“I will do a few test prints and hopefully a large-scale one,” he said. “My goal is to get out something at least two metres tall, which people may see as wall components.”