Wait time for Model 3 drops to two weeks in all-important China market, as Tesla speeds up production in Shanghai

- Tesla delivered 14,954 units, accounting for 23 per cent of the national total, in June

- US carmaker has also lowered deposits for cars to 1,000 yuan from 20,000 yuan

“I waited two months for delivery, but it was worth it,” said Katherine Zhang, who received her Tesla Model 3 in June. “The Autopilot feature is of great help to me, as I’m an inexperienced driver. This is my dream car.”

The sedan, manufactured at the US carmaker’s Gigafactory 3 in Lingang, Shanghai, has helped the marque clinched the top spot in mainland China. In June, Tesla delivered 14,954 units, accounting for 23 per cent of the national total, according to the China Passenger Car Association.

And now, the wait for Model 3s has dropped to just two weeks for Tesla’s mainland fans, after production was ramped up at the Shanghai plant. The reduced wait time was confirmed by a sales manager at Tesla’s showroom at Taikoo Hui shopping centre in Shanghai.

01:20

Tesla starts delivery of made-in-China cars

“An increase in production [in Shanghai] benefited the company,” said Qian Kang, the owner of a Zhejiang-based car components company. “[The Model 3] has become a star model and a key driver of growth in China’s new-energy vehicle segment,” he added.

01:14

Tesla’s first overseas car plant nears completion in Shanghai, outdoing US-China trade war tariffs

Moreover, in the quarter ending June 30, Tesla’s Fremont plant in California, which usually accounts for more than 60 per cent of its global production, was shut for 33 days.

According to venture capital group Loup Ventures, production at the Shanghai factory, also Tesla’s first plant outside the United States, increased from 15,000 units in March to 40,000 units in June. Its annual capacity stands at 200,000 cars.

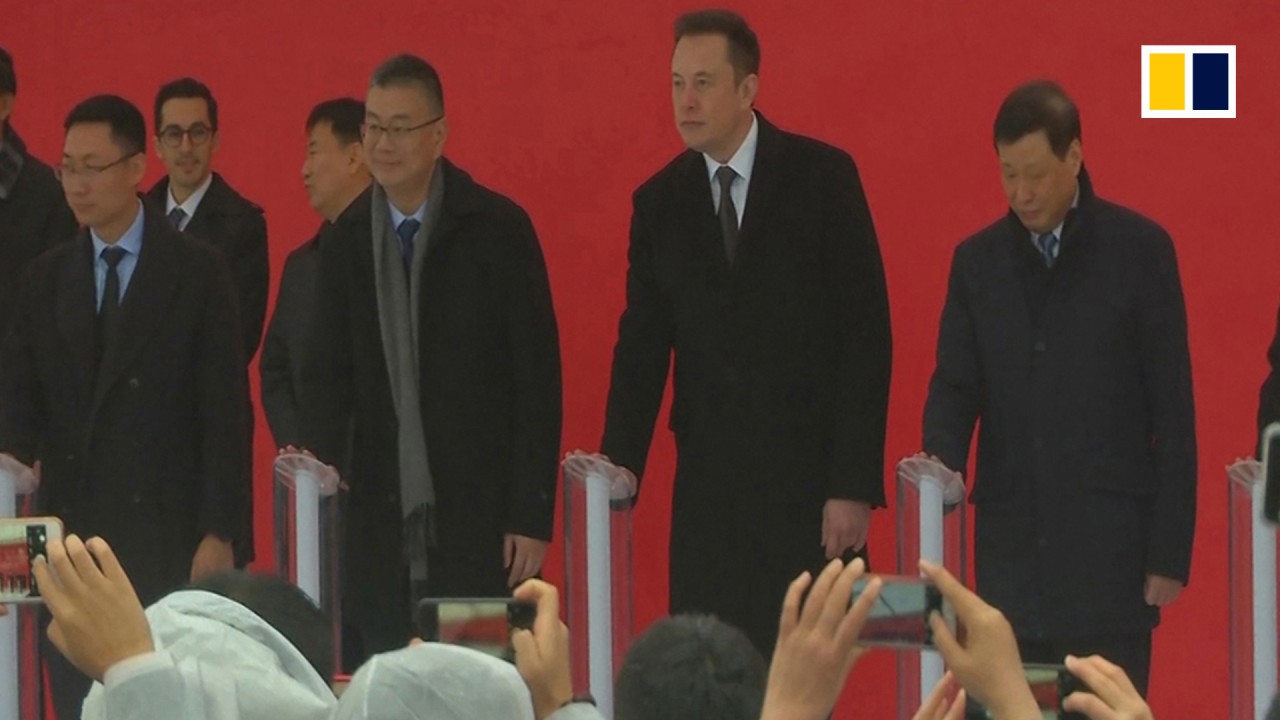

01:25

Tesla breaks ground on first overseas factory in China

Beijing’s 25,000 yuan (US$3,572) subsidy helped Tesla cut the price of the basic Model 3. The car cost 299,050 yuan before April, and 271,550 yuan after the car marker cut its price further in April. This month, the carmaker lowered the amount mainland Chinese buyers needed to deposit for its cars. They are now required to pay a 1,000 yuan deposit instead of the 20,000 yuan earlier.

Moreover, Tesla’s share price has increased by more than US$1,000 this year, making Musk one of the 10 wealthiest billionaires in the world. The company’s valuation has also risen – it is worth several General Motors, even though the conventional auto giant sells way more cars.